There has been advancement of technology in many fields all over the globe, and the arrival of high tech robotics is the next major advancement on the industrial revolution. Several fields including the manufacturing, agricultural, transport and medical sectors are already experiencing efficiency gains, productivity improvements or cost reductions due to automated solutions. In this article, it will look at all the facets of robotic automation and see the ways in which it is changing the world of business. We will discuss the development, issues, and opportunities in robotizing work, across industrial sectors.

A. This paper seeks to explain how and when robotics was born, and how it has developed up to the present

Robotic is a familiar term in this context that dates back to the ancient civilization with mechanical invention like automatons. Today, robotics as a discipline has grown significantly thanks to giant advancements in computing technology and in artificial intelligence and machine learning capacities. A new frontier and continuous advancements were made by the IoT, cloud computing and big data analytics.

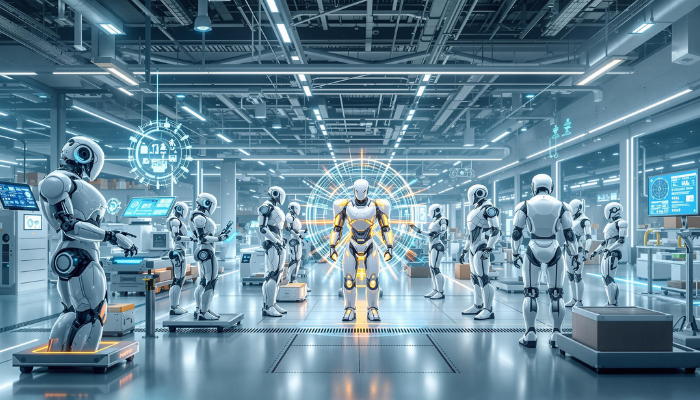

B. What is Robotic Automation?

Robotic automation is the application of robots and other smart technology to handle tasks that normally would be executed by persons. These machines are intended to enhance productivity, quality, and price, gained from labor unpredictability and safety issues. Robotic automation is divided into different categories such as industrial robotic application, service robotic application, as well as humanoid and co-bot robotic application among others.

C. Advantages of Robotic Automation

The implementation of robotic automation in industries worldwide offers numerous benefits, including:

1. Increased Productivity: Automation also enables business to work at any time of the day and night as well as to negotiate at any one time; something that helps in increasing productivity.

2. Cost Reduction: Often, robotic automation enables organizations to minimize the costs on labor and in addition to that, insurance, safety, and training expenses.

3. Improved Quality: By using automation, three major factors are introduced, which include accuracy, uniformity, and reliability all of which leads to an improvement to the quality of the products and thus, customer satisfaction.

4. Enhanced Safety: Risk of work place accidents and injuries are avoided because robots are used to handle dangerous and tedious activities repetitively.

5. Scalability: Robots can be scaled with ease to match the needs of a certain business venture meaning that businesses can easily adjust to the conditions of the market.

D. Applications of Robotic Automation Cross Industries

1. Manufacturing: The sector that experienced the increased use of robotic automation is manufacturing sector, for instance. Use of robots in assembly, welding, and material transport has reduced time for production thereby increasing overall output.

2. Agriculture: Currently, robotic automation has promoted precision agriculture and autonomous farming. Of these, planting, monitoring and harvesting are assumed by robots and drones used in spraying and soil sample analysis thus making food production to be faster, Satyavrat and Tyagi, (2017).

3. Healthcare: Robotic technology has taken a new dimension in the world and especially in the surgical procedures. Robotic surgical systems have been recently adapted to many minimally invasive operations and provide high accuracy, low pain, and quick readmission to normal life for sufferers.

4. Logistics and Transportation: Transportation and logistic sector is one of the leaders where robotic applications have found their way starting from little self-driving cars to automated warehouses. Lithium-ion batteries are ubiquitous in today’s warehouses and ports with applications of self-driving forklifts, mobile robots, and drones providing the greatest value to the supply chain and minimizing delivery times.

E. Challenges and Concerns

Nevertheless, like anything else, robotic automation also has its fair share of problem. Some concerns include:

1. High Initial Costs: Many a time, the use of robotic automation implies some costs which include the cost of purchasing, installing and maintaining the robots. There are times that this could be a major hurdle for the SMBs, or small and medium businesses.

2. Skill Shortages: When full automation is achieved, there shall be adequate demand for employees to work on these automated technologies to reduce or completely eliminate human effort hence a future workforce problem.

3. Job Losses: Automation entails a loss of income that is a major worry considering the aspects of human labor itself. This can lead to adverse societal and economic effects which become a headache to governments and corporate organizations on how best to train or intellect to provide it with new job opportunity.

This thesis’ F. Future Prospects of Robotic Automation

The future for robotic automation is promising and full of great potential and great promise on the horizon. The future development in AI, machine learning system, and IoT will only add to the improvement of robotic automation system. In addition, it is projected that the usage of co-workers robots such as cobots which work accompany with human workers instead of replacing them will raise greatly in order to boost the production at the same time to reduce danger.

Conclusion

In conclusion there is nob doubt that robotic automation is the next big thing that will revolutionize industries across the globe. As highlighted above, the wide ranging advantages such as enhanced performance, reduced cost and enhanced quality have encouraged the use of robotics in different fields. Despite the existing obstacles and the existing skepticism, long term capability of robotic automation exists, and the human society and human operating conditions must be reformed. While more and more companies adopt robotic automation, the problems related to it must be solved to open up a fundamentally new level of increased efficiency, higher productivity, and better incomes.

Very good https://is.gd/tpjNyL

Great insights on strategy and mindset—those are key in any competitive game, whether it’s poker or a high-reward slot like Super Ace Jili.

Creating Ghibli-style art has become surprisingly accessible thanks to tools like Ghibli IA. It’s amazing how AI can turn simple prompts into magical scenes-perfect for fans who want to explore creative storytelling without the technical hurdles.

Balancing luck and strategy in slots is key, and games like Super Ace Jili offer that thrill with wilds and free spins-great for both casual and serious players.

Great breakdown! It’s fascinating how MCP AI bridges AI and real-world data securely. For those diving deeper, check out MCP Customer Data Platforms for practical insights.

Great insights on content efficiency-tools like AI Old Photo to Video Converter take it further by turning stills into engaging motion, blending creativity with smart automation.

Loved the analysis! Tools like Manus AI are changing the game for automating complex workflows-exciting to see AI evolve beyond simple tasks.

Running through subway tracks while dodging trains is a rush! Jake’s moves get smoother with each power-up you collect. If you’re craving that endless runner thrill, check out Subway Surfers Game-it’s addictive and free to play on most platforms.

Great insights on game strategy and user behavior-JiliOK takes it further with AI-driven analysis to boost winning chances. Check it out at Jili No1.

Great insights! For those looking to up their game, platforms like Jilivip offer AI-driven strategies that can sharpen betting decisions. Worth checking out!

In the fast-evolving world of AI, having reliable free tools is a game-changer. Best Free AI Websites does an excellent job curating them, making it easier for users to stay ahead without breaking the bank.

Great insights on e-sports betting strategies! For those diving into online gaming, platforms like JLJLPH offer a seamless mix of slots and live dealer games, making it a solid choice for both new and seasoned players.

Loved the breakdown of AI’s role in streamlining workflows. For a curated look at top tools, check out AI Chat. It’s a goldmine for finding the right solutions without endless searching.